Read and write via OBD the Bosch DCU17PC43 ECUs equipped on several last gen Ford engines.

Work for tuning and repair purposes thanks to the newly supported protocol.

K-SUITE – RELEASE 4.49

The updated protocols concern the TCUS BOSCH ZF8HP and TEMIC DSG, equipped on BMW and VAG vehicles. You can intervene with full reading and writing, thanks to K-TAG, without opening the ECU. What does it mean? Minimized margin of error and maximized numbers of interventions.

The TCUS involved in this update are:

The added Service Mode protocols are what you need to make your job faster, easier, and safer.

You can work on hundreds of new vehicles between BMW and Rolls Royce, Audi, Seat, Skoda, and Volkswagen, in production since 2003 like Golf or Passat, up to the latest 2020 Arteon; BMW 7-Series and Rolls Royce Wraith and Ghost from 2003 to 2013. We cover brands, models, series, and versions among the most popular and sold in the world.

New K-TAG Protocol

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| Bosch | ZF8HP45 | BMW | √ | SERVICE MODE |

| Bosch | ZF8HP50 | BMW | √ | SERVICE MODE |

| Bosch | ZF8HP90 | BMW | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCM Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| Bosch | ZF8HP90 | ROLLS ROYCE | √ | SERVICE MODE |

New K-TAG Protocol

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ250 Exx / Fxx | AUDI | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ250 Exx / Fxx | SEAT | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ250 Exx / Fxx | SEAT | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ250 Exx / Fxx | SEAT | √ | SERVICE MODE |

New K-TAG Protocol

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ381 | AUDI | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ381 | AUDI | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ381 | AUDI | √ | SERVICE MODE |

![]() Read and write in Service Mode.

Read and write in Service Mode.

| TCU Brand | TCU Version | Vehicle Brand | FULL RD/WR | K-TAG Mode |

| TEMIC | DQ381 | AUDI | √ | SERVICE MODE |

Also, to repair and recalibrate the TCUS.

Elaborations

To really get the most out of a vehicle, we need to intervene with reprogramming on the ECU for lower consumption or higher performance. However, with interventions also to the TCU, the vehicle elaboration becomes complete and optimized to the maximum: part of the performance limitations is included in the TCU so, on significant elaborations, it is necessary to also modify the TCU to develop 100% processing.

Repairs

Thanks to the full reading and writing opportunity you can satisfy even more customers because you can repair the TCU, thus avoiding replacing one of most expensive components of the vehicles. A great advantage for the owners of the vehicle and certainly also for your business.

The Service Mode protocols we offer are the most concrete and real answer: we give you reliable solutions that make your job faster, easier, and safer.

To work in Service Mode on these TCMS the new 144300T118 cable shall be used!

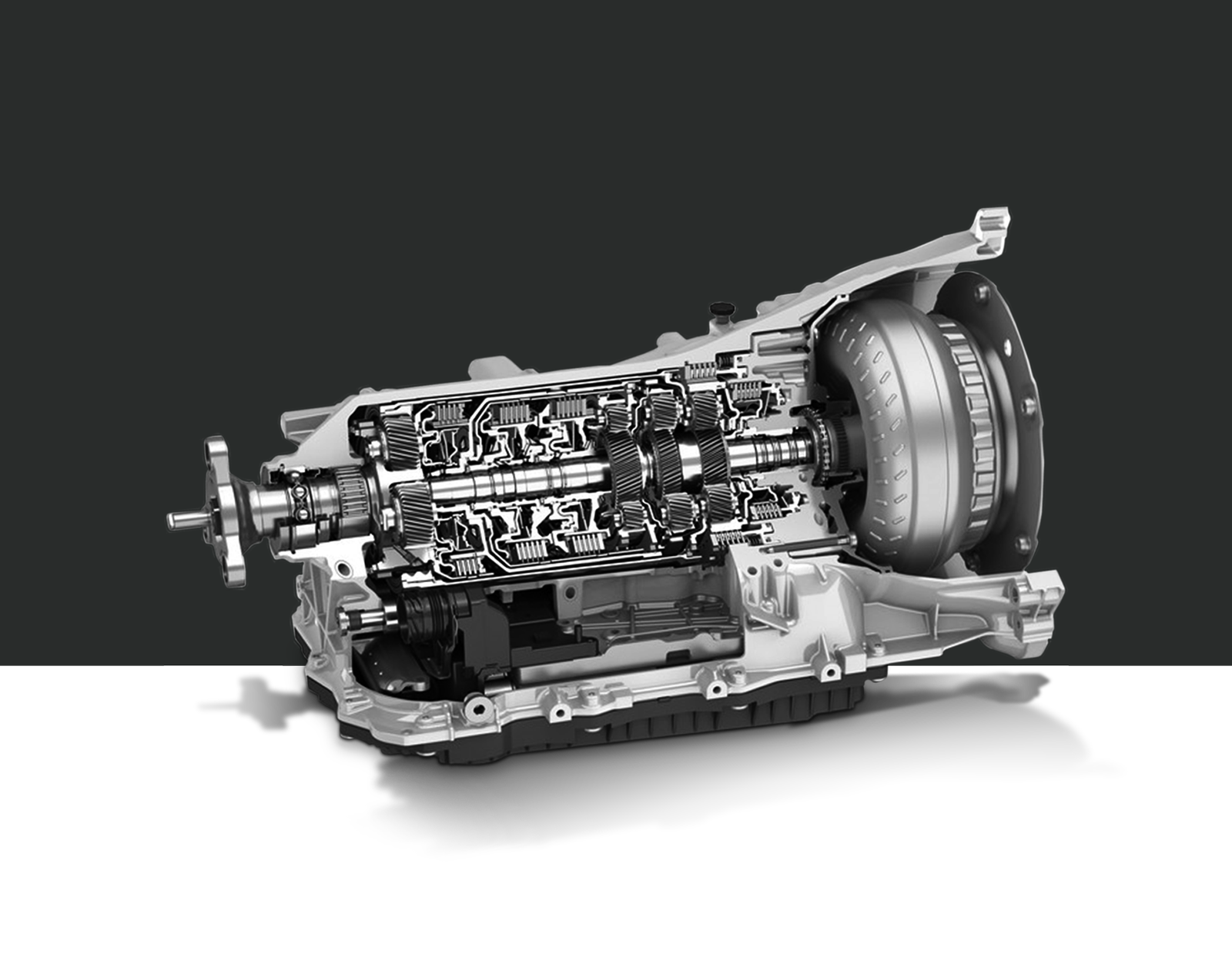

The ZF8HP TCU is one of the most widespread: installed on medium and large displacements vehicles, its excellent reliability is a guarantee for manufacturers. Different versions of this TCU are available, whose difference at a structural level, allows to support more or less engine torque, depending on the model.

In the case of BMW, in this specific release, we have:

ZF8HP45: maximum torque 450Nm for gasoline versions, 500Nm for Diesel versions

ZF8HP50: maximum torque 500Nm in both versions.

ZF8HP90: maximum torque 900Nm for gasoline versions, 1000Nm for Diesel versions

All these TCUS with ZF8HP designations are at 8 eight-speed gearbox and torque converter.

The main prerogative of this gearbox is that it totally differs from a “traditional” transmission, because the various gears are managed by planetary groups, meaning elements composed by 3 elements: sun gear, planet carrier and ring gear. The whole is alternated by multidisc clutches, that allows, by braking these components, to go between speeds by combining various planetary groups.

In order to have the gear change, there is an electronic management that acts on solenoid valves that move these clutch groups, to switch between speeds. The faster these clutches move, the higher the shifting speed is, and the less smooth is the gear passage.

To improve performances of this gearbox you can intervene on torque parameters, on the timing maps – related to the movement of clutch and shifting regimes.

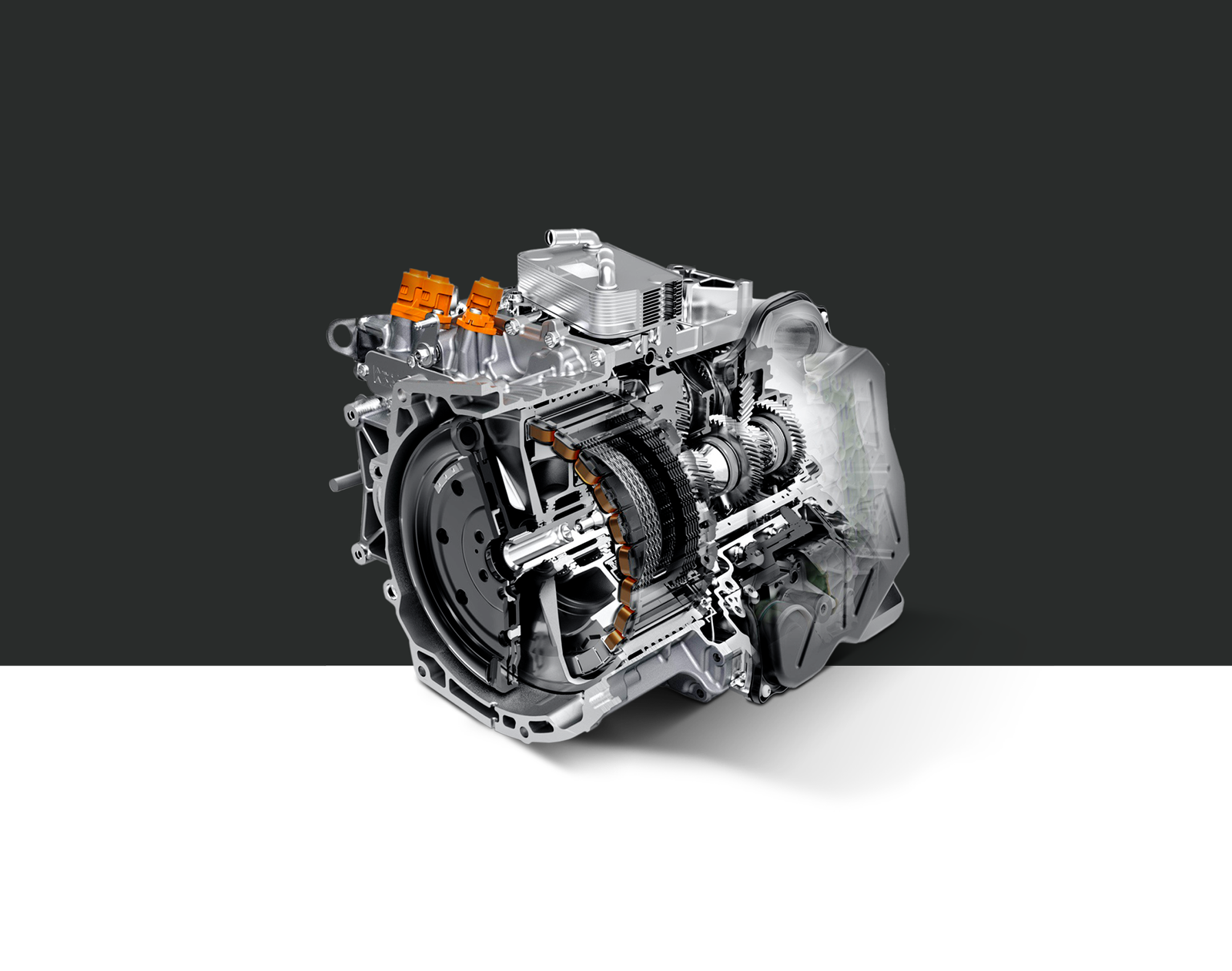

The DSG6 was the first dual-clutch automatic transmission produced by VAG in 2003. It is a revolution that led to a radical change in the driving concept, in addition to opening the way to automatic transmissions production, intended for non-premium vehicles; just think that in 18 years of production have been sold over 26 million of cars equipped with DSG!

The first car to equip this gearbox was the R32 Golf, introducing the “R” logo, that still today wears the most powerful and sporty versions of the Wolfsburg compact car.

The transmission is designed, like all “DQ” gearboxes, for transversal mounted engines and holds a maximum torque of 400Nm, besides this you can use it for both front-wheel and four-wheel drive models.

In this case, the gearbox uses two primary shafts that respectively operate the even and odd gears linked to two wet multidisc clutches. What allows the speed in shifting of this transmission is the fact that while driving the gearbox has both primary shafts with engaged gear, that’s why, to complete the transition from one gear to another, it will only be necessary to move the two clutches to disconnect the shaft with the previous gear and to engage the shaft with the next gear. Obviously, the scaling has the same principle of operation.

The automatic transmission is managed by an ECU that, based on the parameters set in the map, reduces, or increases the torque, depending on whether you up or downshift. Furthermore, the TCM applies the rev matching during downshifting, the “sailing” mode in the last versions and also the “Tiptronic” mode (sequential manual gearbox).

The parameters you can work to improve gearbox performances are torque and rpm limitations, oil pressure of the hydraulic actuators, times and shifting threshold.

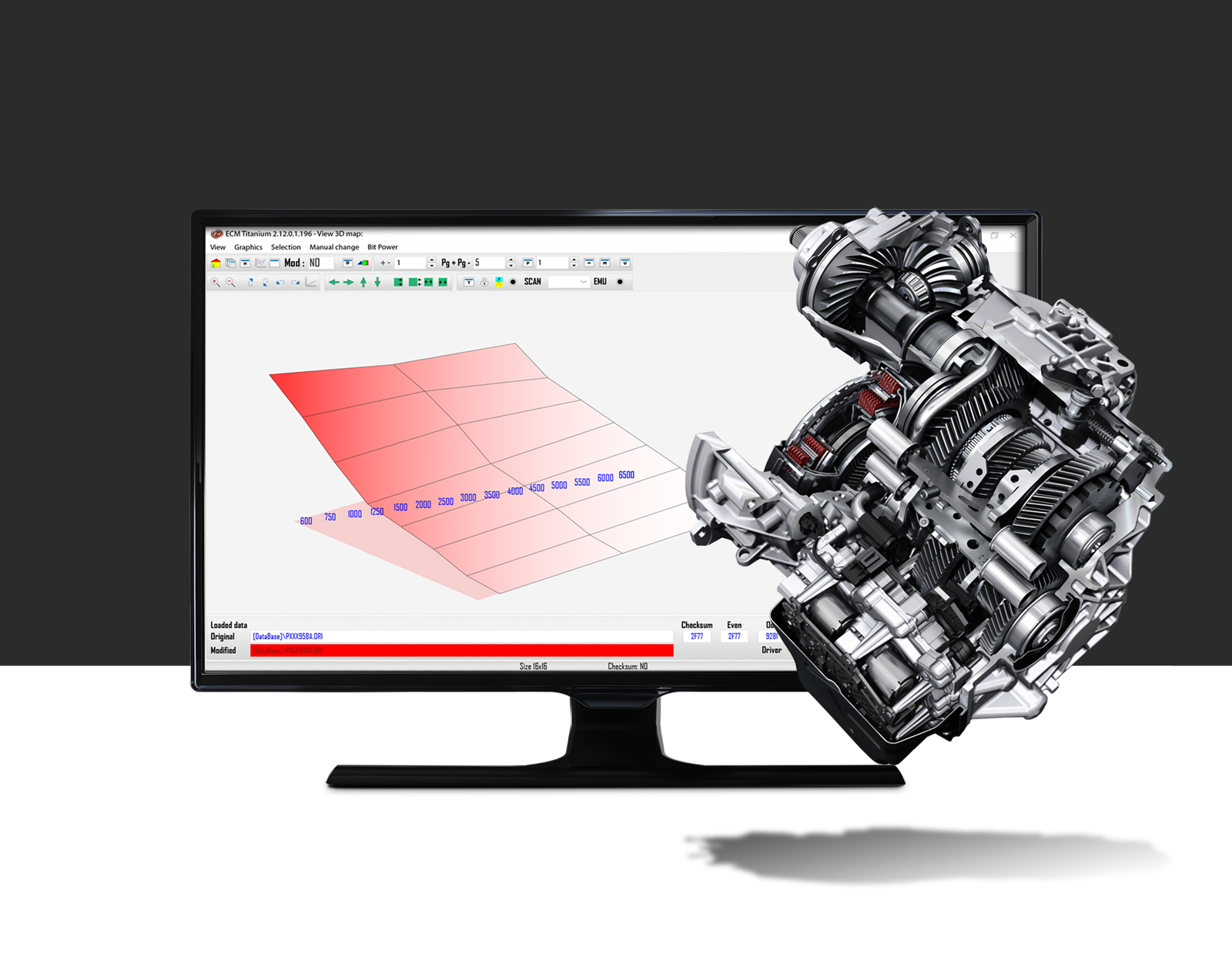

Thanks to K-TAG Service Mode new protocols and to ECM Titanium remapping software you are autonomous and independent in every application.

Made available on the European Market in 2017, the DQ381 is an evolution of the DSG7 DQ380 gearbox, launched in 2015 and applied mainly on the VAG group vehicles, sold on the Chinese market.

Also in this case, like DQ250, we have multidisc twin clutches, but speeds go from 6 to 7 and the maximum torque handled by the transmission from 400 to 420Nm. It is available in two variants, DQ381-7A and DQ381-7F, respectively used on all-wheel-drive vehicles (7A) or front-wheel drive (7F).

The functioning principle of the transmission is like the DSF6 DQ250 one: the transmission is composed by the two primary shafts, to which the multidisc clutches are linked, that handle even and odd gears respectively. Unlike the six-speed versions, DSG7 has an additional shaft for reverse, not present on DSG6, because connected directly to the secondary shaft that manage 5^ and 6^ gear.

Even in this case, the electronic management to which the gearbox relies on allows to manage the various engine parameters. The objective is to make the transition between one gear and the other as fluid as possible, going to intervene on the torque parameters delivered of the engine and allowing the “sailing” mode, launch control and Tiptronic.

To improve transmission performances, it is possible to work on the rpm parameters, maximum engine torque output, shift times and Launch Control management.

We help you work even on these TCUS quickly and efficiently thanks to K-TAG and ECM Titanium.

Work for tuning and repair purposes thanks to the newly supported protocol.

Intervene for tuning and repair on the supported new motorcycles and ATVs.

Even more possibilities for modification and customization are available for KTM, Husqvarna and GasGas motorbikes.

Offer a comprehensive service to your customers thanks to new protocols for KESS3.

Expand your workshop’s capabilities in the heavy-duty vehicle field with KESS3.

Even more possibilities for modification and customisation are available for KTM, Husqvarna, GasGas, Triumph and Suzuki motorbikes.